NEWS

Company News

The 13 most common methods and precautions for damaging the mechanical seals

TIME:2023-06-29

01 Dry operation

Do you hear the burst? It's the sound of the mechanical seal in dry operation.Mechanical seals are designed to use a small amount of flow fluid between the sealing surfaces that will remain lubricated and cooled.However, when the liquid vaporizes between the sealing surfaces, an audible burst sound occurs.

The following are the common reasons for the lubrication / coolant vaporization:

1)The axial adjustment is improper

2)Entrapped air

3)Steam retention in stuffing box

4)Solid retention in stuffing box

5)Pump dry operation

6)Cooling is insufficient

7)No or incorrect flushing scheme installed

8)Fluid vapor pressure is too high

Figure 1: Example of severe thermal damage (coking) resulting from dry operation

Figure 2: Damaged to the sealing surface due to dry operation and mechanical deformation

How to prevent or repair it

To prevent dry operation, keep heat away from the mechanical sealing surface by increasing the flushing flow or reevaluating the structural design of the packing letter, sealing flushing system or flushing scheme.The trapped steam is released by emptying the gas in the packing lid or by using the tapered hole packing lid.

02 High temperature

If radial cracks (thermal cracks) or deposits (coking) are seen on the sealing surface, it may be caused by excessive temperature.In this case, the high temperature faced by the seal is caused by the heat generated during the pump or seal operation.

Heating crack

Thermal cracks can be identified by radial cracks that appear in the center of the sealing surface (see Figure 3).These cracks act as cutting blades, causing premature wear when the sealing surfaces rub against each other.

Figure 3: Radial thermal cracks originating from the center of the sealing surface

Coking

Coke will leave up debris or grinding debris on the atmospheric side of the mechanical seal.This accumulation occurs when the seal is operating at too high temperature, but may also occur due to unclean irrigation fluid or contamination from the external environment (see Figure 4).

Figure 4: Example of coking

Excessive heat is generated when the pump (on the performance curve) runs away from the BEP; The seal generates excessive heat due to high speed operation or excessive pressure on the sealing surface.

Certain sealing materials are not designed for high-temperature applications.When pumping high temperature liquids, if the wrong structural material is used, it will lead to premature failure of the mechanical seal.

How to prevent or repair it

Keeping the seal cool is essential for its long-term and reliable operation. If signs of hot cracking or coking can be seen, then it is time to take a closer look at the sealed flush regimen (or if it is necessary to add the sealed flush regimen).

Consider increasing the flushing flow rate or changing the flushing regimen. Is the seal properly chosen for the application? The correct structural materials and seal design ensure that the seal can withstand high temperatures.

03 Impact

There are several different types of shocks that can cause mechanical seal failure, including mechanical and thermal shocks.

Figure 5: Example of an impact injury

Mechanical impact is caused by the deterioration of equipment operating conditions, such as bearing damage, cavation, excessive torque, uneven load and wrong shaft. More commonly, however, the mechanical impact is caused by improper sealing operation and improper assembly.

Thermal shock occurs when the seal faces large temperature fluctuations in a short time. Different areas of the sealing surface will appear in different degrees of expansion and contraction, thus causing excessive stress or strain on the sealing surface.

How to prevent or repair it

How to solve this particular situation? The first step is to fully understand why it happens. Here are some things to keep in mind when dealing with shocks:

1)When installing mechanical seals, avoid fastening fasteners unevenly or too tightly

2)Care is taken to ensure that a flushing scheme matching the seal is installed

3)Check to ensure that the flushing fluid and quench system are designed to minimize possible momentary outages

4)Add vibration checks to routine project inspections

5)If the operating parameters specify a large temperature difference, as a general rule of thumb, limit the variation to 1 F per minute.

04 Poor lubrication

If the mechanical seal screams during operation, the reason may be the lack of lubrication between the sealing surfaces.Lubrication plays a key role in the operation of mechanical seals.In addition to its functions of lubrication, there are cooling, sealing, cleaning sealing surface and protection.

Poor lubrication on hard surfaces, such as silicon carbide or ceramics, can cause thermal cracking. Hot cracks indicate radial cracks on the sealing surface. The height and distance between cracks can range from very small to very large (see Figure 6).

When two rotating surfaces come into contact under heavy loads, local high temperatures may occur due to excessive friction heating near the surface. Heat, poor lubrication between sealing surfaces and superposition of mechanical loads cause cracking of the material near the contact area.

Figure 6: Example of poor lubrication damage

How to prevent or repair it

Confirm that the pressure of the sealing chamber and other operating conditions are within the limit range of the sealing design; Verify that air has been or can be discharged sufficiently from the sealing chamber; Provide adequate continuous (lubricated) flushing for the seal.

05 RPM / torque

This is true of almost any rotating device, and the rotational speeds are often fatal. High start or running torque, frequent start / stop of the equipment can cause damage to the mechanical seal.

Figure 7: Example of a high-torque injury

How to prevent or repair it

Check the condition of the equipment and repair it to the appropriate limits. Select the appropriate driving mechanism according to the torque or other equipment operating conditions. Use a balanced seal to reduce the sealing surface torque and the pressure torque.

06 Chemical attack

Some of the most serious damage to mechanical seals can come from chemical erosion. Incompatible materials can have a huge impact. When a seal is chemically eroded, any of the following may occur:

1)Severe leakage

2)Signs of excessive wear

3)Fragile or broken parts

4)Sealed surface point erosion

5)Corroded metal parts

6)The expanding O-ring

Figure 8: Example of chemical erosion damage

Chemical erosion is caused by improper selection of seals and their structural materials. The selection of mechanical seals must be carried out by people who have extensive experience with the different materials of mechanical seals and also understand the way certain chemicals react, which is crucial.

How to prevent or repair it

To properly select the appropriate material for the flow fluid, a complete chemical analysis should be completed. When selecting sealing materials, please understand all possible operating conditions of the seal, including the characteristics of cleaning chemicals and their operating temperature. Select a rinse protocol that will use clean, compatible liquids. In some cases, dual mechanical seals may be required to neutralize or control the corrosive environment.

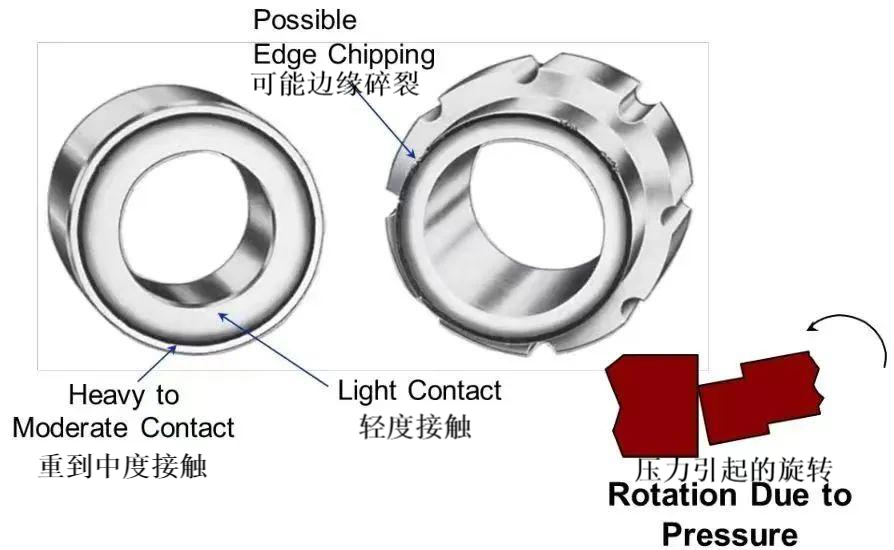

07 Pressure

Overpressure of the mechanical seal will cause gravitational contact at the outer diameter of the dynamic and static ring sealing surface, and gradually reduce inward until there is almost no visible contact. High pressure can cause cracking (notching) on the outer diameter edge of the main seal ring.

Figure 9: Example of overpressure damage

How to prevent or repair it

Reduce the sealing chamber pressure as much as possible. In order to reduce deformation due to high sealing chamber pressure.

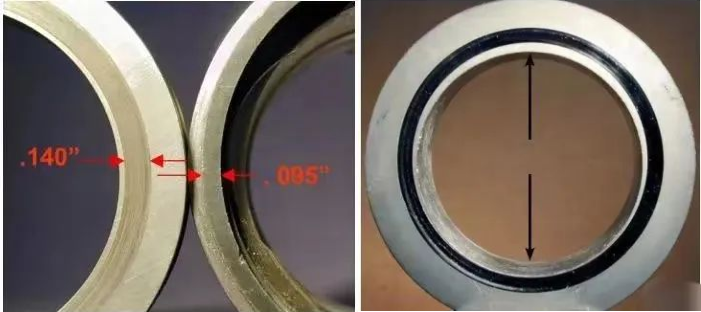

08 Solid particles

Solid particles (abrasive) + wrong sealing material = Seal wear is much faster than expected.

The damage caused by solid particles to the sealing surface has the following signs:

1)The sealing surface is severely worn

2)The worn grooves have the appearance of a "phonograph record"

3)Margin fragmentation or reverse rounding may occur on the sealing surface

Figure 10: Example of solid particle damage

How to prevent or repair it

Before application in the case of solids, the characteristics of the fluid, including solids content, solids size and solids type, must be determined.

Select the appropriate structural material, or seals specifically designed for solid particle-containing applications. Next, look at the rinse scheme. Modify the flushing arrangement so that the flushing fluid is flushed on the sealing surface, increase the flushing speed, and increase the sealing cavity pressure by installing the throat bushing.

09 Out of alignment

Misalignment is one of the most common causes of damage to mechanical seals. Misalignment can be caused by pipe strain, deflection during hard start, shaft runout, and countless other conditions. Misalignment can put excessive pressure on mechanical seal components, causing them to fail to function properly, wear prematurely, and eventually fail.

Figure 11: Example of misalignment damage

How to prevent or repair it

Be sure to follow the correct installation guidelines and use tools such as laser calibration to ensure that the pump rotor fits correctly. However, the pump may fail during operation, even if it is completely correct during installation. Equipment displacement caused by thermal expansion and dynamic load changes may drive the pump out of direction.

10 Vibration

Vibration can cause problems with almost any type of equipment, from pump to fan. How to determine whether the vibration is the main culprit of the mechanical seal failure?

Figure 12: Example of vibration damage

Just like misalignment, vibrations can come from many sources:

1)Out-off-balance

2)Misalignment

3)Run away from the BEP

4)Pump cavitation

5)Entrapped air

6)Improper pipeline design

How to prevent or repair it

Proper installation of equipment is essential to solve vibration problems. Pump base should be properly installed and grouted to prevent soft foundation. The pump shaft should also be laser aligned with the motor shaft. OEM spare parts should be used. Vibration problems may occur when parts exceed the dimensions and tolerances specified in the design. Finally, proper piping technology (according to ANSI/HI standards) can have a significant impact on minimizing vibration.

11 Installing error

The mechanical seal is easily damaged during installation. Here are some common installation errors in mechanical seals:

1)The end face of the mounted stuffing box is not perpendicular to the shaft

2)Install the coupling to the shaft by hammering

3)Insufficient or improper lubrication for mounting (sliding) mechanical seals onto shafts

4)The installation procedures described in the mechanical seal manual were not followed

Figure 13: Example of damage resulting from not following all installation steps

How to prevent or repair it

Mechanical seals need to be careful during handling and installation. Here are some tips for the installation process:

1)Do not remove mechanically sealed packaging before formal installation

2)Wash your hand clean before installation! Even tiny particles or oil on the skin can wear and leak on the sealing mating surface during operation

3)Do not touch the sealing mating surface by hand

4)Place a clean wrapping paper on the workbench to prevent contamination of the mechanical sealing

5)Clean the sealing surface with a clean soft cloth and an approved solvent before mounting the mechanical seal to the pump

6)Use the manufacturer's recommended lubricant as per the installation instructions

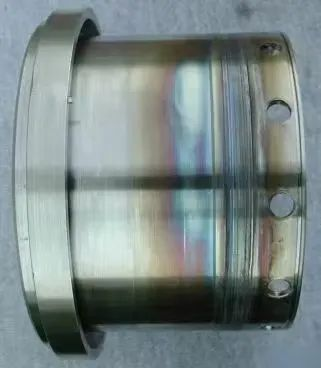

12 Install a new seal on the worn pump

Check and ensure that the pump (parts fitting the seal) is in good condition before installing and / or replacing the mechanical seal.

A scratched shaft or sleeve may damage the mechanical seal before the mechanical seal runs; the scratched shaft and sleeve will damage the O-ring when installing (sliding into) the mechanical seal. Bended pump shaft, old and non-conforming bearings, unbalanced impeller can cause vibration, internal dynamic / static parts touching the pump, bearing damage, etc., all of which will shorten the life of the mechanical seal.

Figure 14: Severely scratched bushing

How to prevent or repair it

All used parts shall be thoroughly inspected before reuse to ensure they meet the design dimensions and tolerances. If the used part size exceeds the design requirements, the new part should be replaced.

13 Error operation

There is no doubt that accidents happen frequently. Whether starting the pump improperly or running the pump with the valve closed, these accidents can have costly consequences.

Improper pump startup may cause motor trip, shaft distortion, and even abnormal movement of the mechanical seal. The dry start pump means that all problems encountered in the # 1 method will eventually damage the mechanical seal. Operating the system with the suction valve closed (dry operation) or the outlet valve closed (Close the lift) causes premature seal failure.

How to prevent or repair it

Ensure that all operators are trained to properly start the pump set and system operating procedures.

Sum up

To reduce seal failure, review all stages of the equipment application-how to select the seal device, installation practice, and all through to operation. Sealing failures are often reproducible. If the seal operates in the same manner, the same failure rate is expected.

Previous:Knowledge of Selection of Mechanical Sealing Materials

Next:Selection of mechanical seal category, seal type and arrangement mode

+86-0335-8085559

Junming (Hebei) Machinery and Equipment Manufacturing Co., Ltd.

Address:No.1 Huaihe Road, Qinhuangdao Economic and Technological Development Zone

Domestic:+86-0335-3066990

Overseas:+86-0335-8085559

Domestic:info@junmingmeco.com

Overseas:sales@junmingmeco.com

Website:www.junmingmeco.com

-

官方微信

Recommendation

Recommendation