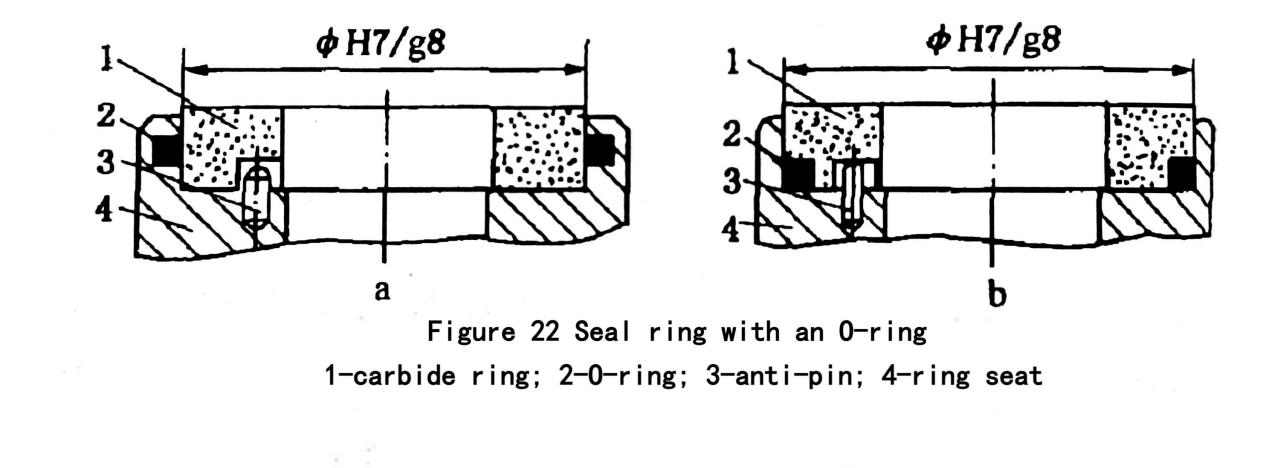

What is the structure of the combined sealing ring with the O-ring?

TIME:2024-02-06

This combined sealing ring slides with H7 / g8 between the carbide ring and the ring seat. An O-ring seal made of polytetrafluoroethylene or synthetic rubber is placed between the two cylindrical surfaces to prevent the leakage of the sealing fluid in between, and to combine the carbide ring with the ring seat. A pin is set at the plane junction of the carbide ring and the ring seat to transfer the torque. This kind of combined structure, no combined stress, there is no resulting deformation of the sealing end surface of the combined sealing ring, but the number of parts of the combined sealing ring has increased, but also need to hole or groove in the carbide ring, increasing the difficulty of manufacturing, and due to the addition of the O-ring, the use temperature of the sealing ring is limited.

Previous:What else is the compensation mechanism besides the spring?

Next:Thermal power plant stator cooling pump non-assembly machine seal

+86-0335-8085559

Junming (Hebei) Machinery and Equipment Manufacturing Co., Ltd.

Address:No.1 Huaihe Road, Qinhuangdao Economic and Technological Development Zone

Domestic:+86-0335-3066990

Overseas:+86-0335-8085559

Domestic:info@junmingmeco.com

Overseas:sales@junmingmeco.com

Website:www.junmingmeco.com

-

官方微信

Recommendation

Recommendation