NEWS

Company News

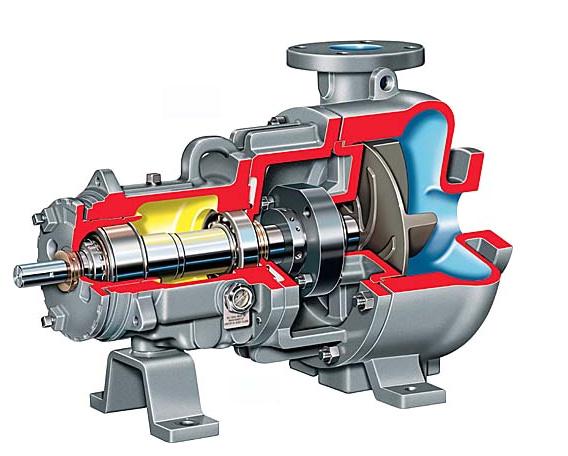

Analysis of the common problems in the application of water pump mechanical seal

TIME:2022-11-22

Pump mechanical sealing belongs to the key vulnerable parts, the failure of pump mechanical seal leakage is one of the most likely to appear in the pump failure, several common problems in the use of pump mechanical sealing to do a simple analysis.

- Is the greater the compression amount of the water pump mechanical sealing spring, the better the sealing effect?

- Is the tighter the moving ring ring, the better?

- The tighter the static ring sealing ring, the better?

- Is the impeller nut closer the better?

In the mechanical seal leakage, the leakage between the shaft sleeve and the shaft is relatively common. It is generally believed that the leakage between the shaft is the impeller lock mother is not locked, in fact, there are many factors leading to the leakage between the shaft, such as the failure of the shaft pad, offset, impurities between the shaft, the coordination between the shaft and the sleeve has a large shape error, the contact surface damage, the gap between the components on the shaft, the shaft thread is too long will lead to the leakage between the shaft. Excessive lock lock will only lead to the premature failure of the shaft pad, on the contrary, moderate lock lock, so that the shaft pad always maintain a certain compression elasticity, in the operation of the lock will automatically timely lock, so that the shaft is always in a good sealing state.

Previous:The basic structure of mechanical seals and their function and requirements

Next:Three reasons of failure of sealing function

+86-0335-8085559

Junming (Hebei) Machinery and Equipment Manufacturing Co., Ltd.

Address:No.1 Huaihe Road, Qinhuangdao Economic and Technological Development Zone

Domestic:+86-0335-3066990

Overseas:+86-0335-8085559

Domestic:info@junmingmeco.com

Overseas:sales@junmingmeco.com

Website:www.junmingmeco.com

-

官方微信

Recommendation

Recommendation