NEWS

Company News

Pump Basics

TIME:2023-08-29

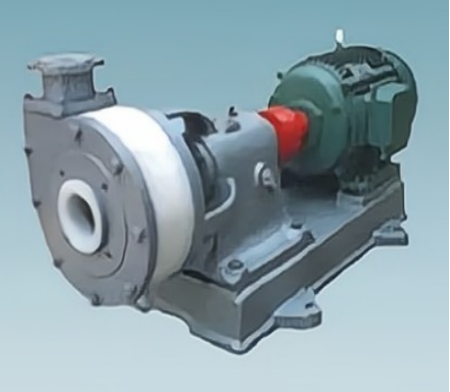

1.What is a pump?

A pump is a machine that transports or pressurizes a liquid.It transfers the mechanical energy of the prime mover or other external energy to the liquid to increase the energy of the liquid.

The pump is mainly used to transport liquids such as water, oil, acid and alkali liquid, emulsion, suspoemulsion and liquid metal, and can also transport liquid, gas mixture and liquid containing suspended solids.

Pumps can usually be divided into three categories according to their working principles: positive displacement pumps, dynamic pumps and other types of pumps.In addition to classification by working principle, it can also be classified and named by other methods.For example, according to the driving method, it can be divided into electric pumps and water wheel pumps; according to the structure, it can be divided into single-stage pumps and multi-stage pumps; Water pumps, oil pumps and mud pumps, etc.

There is a certain interdependence relationship among the various performance parameters of the pump, which can be expressed by drawing a curve, which is called the characteristic curve of the pump, and each pump has its own specific characteristic curve.

2. The definition and historical source of the pump

A machine that transports liquids or pressurizes liquids.A pump in a broad sense is a machine that transports fluid or pressurizes it, including some machines that transport gas.The pump transfers the mechanical energy of the prime mover or the energy of other energy sources to the liquid to increase the energy of the liquid.

The promotion of water is very important for human life and production.Various water-lifting appliances existed in ancient times, such as chain pumps in Egypt (17th century BC), oranges in China (17th century BC), windlasses (11th century BC), waterwheels (1st century AD), and 3rd century BC The screw rod invented by Archimedes in ancient Greece.Around 200 BC, the ancient Greek craftsman Ctesibius invented the most primitive piston pump - the fire pump.As early as 1588, there was a record about the 4-blade sliding vane pump, and various other rotary pumps appeared one after another.In 1689, D. Papin of France invented the volute centrifugal pump with 4 blade impellers.In 1818, a centrifugal pump with radial straight blades, a semi-open double-suction impeller and a volute appeared in the United States.From 1840 to 1850, HR Worthington in the United States invented a piston pump with direct steam acting on the opposite pump cylinder and steam cylinder, marking the formation of modern piston pumps.From 1851 to 1875, multi-stage centrifugal pumps with guide vanes were invented one after another, making it possible to develop high-lift centrifugal pumps.Subsequently, various pumps came out one after another.With the application of various advanced technologies, the efficiency of pumps has gradually increased, and the performance range and applications have also expanded.

3. Basis for the classification of pumps

(1) Working principle

1) The working principle can be divided into vane type, volumetric type and other forms.

①The vane pump, relying on the dynamic action of the rotating impeller on the liquid, continuously transfers energy to the liquid, increasing the kinetic energy (mainly) and pressure energy of the liquid, and then converts the kinetic energy into pressure energy through the extrusion chamber, which can also be used Divided into centrifugal pumps, axial flow pumps, partial flow pumps and vortex pumps.

② Positive displacement pumps rely on periodic changes in the volume of the sealed working space containing the liquid to periodically transfer energy to the liquid, increasing the pressure of the liquid to forcibly discharge the liquid. According to the movement form of the working element, it can be divided into reciprocating pumps and rotary pumps.

③ Other types of pumps that transfer energy in other forms. For example, the jet pump relies on the high-speed injection of the working fluid to inhale the fluid to be transported into the pump and mix it for momentum exchange to transfer energy; the water hammer pump uses part of the water in the flow to be raised to a certain height during braking to transfer energy; the electromagnetic pump uses The electrified liquid metal generates flow under the action of electromagnetic force to achieve transportation. In addition, pumps can also be classified according to the nature of the liquid to be transported, the driving method, the structure, and the purpose.

2) Classified according to the number of working impellers

① Single-stage pump: that is, there is only one impeller on the pump shaft.

② Multi-stage pump: There are two or more impellers on the pump shaft. At this time, the total lift of the pump is the sum of the lifts generated by n impellers.

3) Classified by working pressure

① Low-pressure pump: the pressure is lower than 100 meters of water column;

② Medium-pressure pump: the pressure is between 100 and 650 meters of water column;

③ High-pressure pump: the pressure is higher than 650 meters of water column. (Multi-stage centrifugal pumps can reach 2800m)

4) Classified according to the water inlet method of the impeller

① Single-side water-inlet pump: also called single-suction pump, that is, there is only one water inlet on the impeller;

②Double-suction pumps, that is, there is a water inlet on both sides of the impeller. Its flow is twice as large as that of single-suction pumps, and it can be approximated as two single-suction pump impellers placed back to back.

5) Classified according to the joint joint form of the pump casing

① Horizontal split pump: that is, there is a joint joint on the horizontal plane passing through the axis line. (The most common horizontal split pump is double-suction pump)

②Vertical joint surface pump: that is, the joint surface is perpendicular to the axis line.

6) Classified according to the position of the pump shaft

① Horizontal pump: the pump shaft is in a horizontal position.

② Vertical pump: the pump shaft is in a vertical position.

7) Classified according to the way the water from the impeller is led to the discharge chamber

① Volute pump: After the water comes out of the impeller, it directly enters the pump casing with a helical shape.

② Guide vane pump: After the water comes out of the impeller, it enters the guide vane set outside it, and then enters the next stage or flows into the outlet pipe. (Usually used in multistage pumps and axial flow pumps)

(2) Operating principle

The impeller composed of several curved blades is placed in the pump casing with a volute channel. The impeller is fastened on the pump shaft, and the pump shaft is connected with the motor, which can be driven to rotate by the motor. The suction port is located in the center of the pump casing and connected to the suction pipe, and a check valve is installed at the bottom of the suction pipe. The side of the pump casing is the discharge port, which is connected with the discharge pipeline and equipped with a regulating valve.

The reason why the centrifugal pump can transport liquid mainly depends on the centrifugal force generated by the high-speed rotating impeller, so it is called centrifugal pump.

The working process of the centrifugal pump:

Before starting the pump, fill the pump with the liquid to be transported.

After the pump is turned on, the pump shaft drives the impeller to rotate at high speed to generate centrifugal force. Under this effect, the liquid is thrown from the center of the impeller to the periphery of the impeller, the pressure increases, and it flows into the pump casing at a high speed. In the pump casing, due to the continuous expansion of the flow channel, the flow rate of the liquid slows down, so that most of the kinetic energy is converted into pressure energy. Finally, the liquid flows into the discharge pipe from the discharge port with a relatively high static pressure. After the liquid in the pump is thrown out, a vacuum is formed in the center of the impeller, and under the pressure difference between the liquid surface pressure (atmospheric pressure) and the pump internal pressure (negative pressure), the liquid enters the pump through the suction pipeline, filling up the Exclude the position of the liquid.

When the centrifugal pump is started, if there is air in the pump casing, since the density of the air is much smaller than that of the liquid, the centrifugal force generated by the rotation of the impeller is very small, and the low pressure generated at the center of the impeller is not enough to create the vacuum required to absorb the liquid. , the centrifugal pump cannot work. In order to make the pump full of liquid before starting, a check valve is installed at the bottom of the suction pipe. In addition, a regulating valve is also installed on the outlet pipeline of the centrifugal pump for starting and stopping and regulating flow.

Previous:Guide for selecting mechanical sealing materials

Next:Seven forms of dynamic sealing commonly used in the mechanical design

+86-0335-8085559

Junming (Hebei) Machinery and Equipment Manufacturing Co., Ltd.

Address:No.1 Huaihe Road, Qinhuangdao Economic and Technological Development Zone

Domestic:+86-0335-3066990

Overseas:+86-0335-8085559

Domestic:info@junmingmeco.com

Overseas:sales@junmingmeco.com

Website:www.junmingmeco.com

-

官方微信

Recommendation

Recommendation