NEWS

Company News

Seven forms of dynamic sealing commonly used in the mechanical design

TIME:2023-09-20

The sealing problem of dynamic equipment is always existing with the operation of the equipment. Today, for you to sort out the common kinds of sealing forms, use range and characteristics of dynamic equipment, so that you have a deep understanding of the sealing problem.

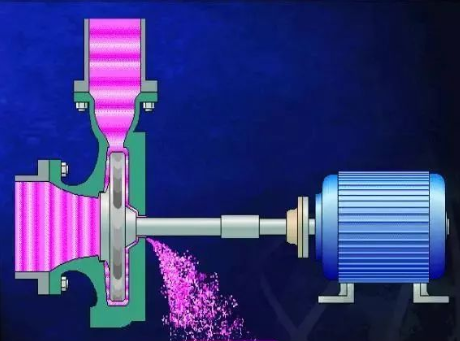

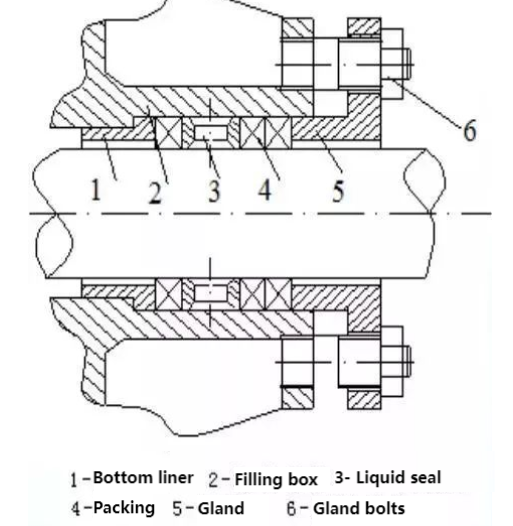

1.Packing seal

According to its structural characteristics, the packing seal can be divided into:

○ Soft stuffing-box seals

○ Hard filler sealed

○ Forform packing seal

Soft stuffing-box seals

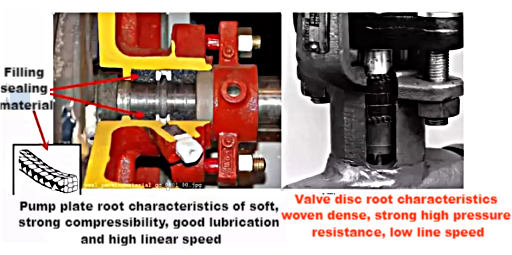

Soft filler type:disk root

The disc root is usually made of soft lines, filling the sealing cavity with a square section area, and produces pressure force on the cover, so that the packing is pressed on the sealing surface (the outer surface of the shaft and the sealing cavity), producing the radial force of the sealing effect, to achieve the sealing effect.

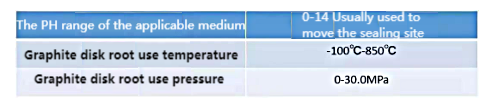

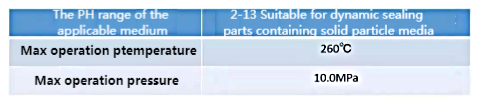

Suitable occasions of soft packing:the selection of the root packing materials determines the sealing effect of the root. Generally speaking, the root manufacturing materials are affected by the temperature, pressure and pH of the field medium, and when choosing the material of the root, it is also necessary to consider the surface roughness, eccentricity and linear speed of the mechanical equipment working by the root.

A.Graphite disk root is characterized by high temperature resistance, high pressure resistance, corrosion resistance, excellent sealing performance, and stable and reliable function. It is one of the most effective products to solve the problem of high temperature and high pressure sealing.

B.Aramid dish root is a high strength organic fiber soaked by impregnated PTFE emulsion and lubricant.

C.PTFE root is pure PTFE dispersed resin as raw material, first made of raw film, and then through twisting, woven into the root. Often widely used in food, pharmaceutical, paper making chemical fiber and other high cleanliness requirements, and has a strong corrosive medium on the valve, pump.

2.Hard filler seal

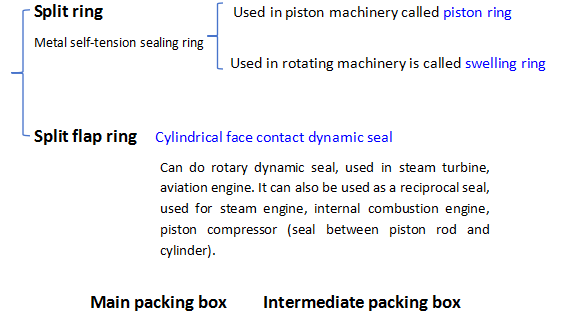

The hard packing seal has two categories: split ring and split flap ring.

2.Mechanical seal

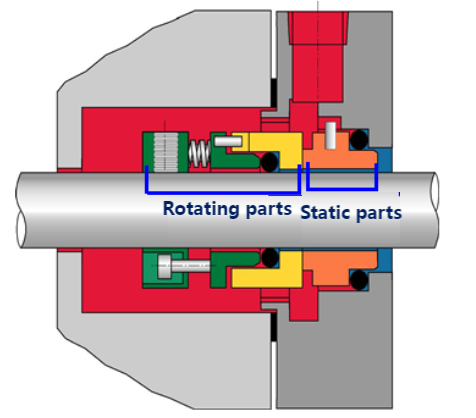

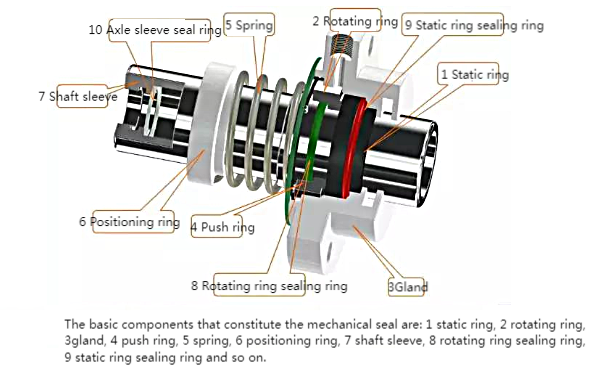

The seal is composed of two parts: rotating parts and static parts (see the figure below), and the static torus becomes the main sealing surface.

Mechanical seal is also known as end surface seal, according to the relevant national standards defined as: by at least a pair of end face vertical to the rotation axis of the fluid pressure and the elastic force (or magnetic force) and the auxiliary seal, and to prevent fluid leakage device.

3.Dry gas seal

Dry gas seal, namely "dry operation gas seal", is a new type of shaft end seal that uses the slotted sealing technology for gas sealing, which belongs to the non-contact seal.

Features:good sealing performance, long life, no need for sealing oil system, less power consumption, simple operation and low operation and maintenance costs. Dry gas seal, as a maintenance seal system that does not require any sealing end surface cooling and lubrication oil, is replacing the floating ring seal and maze seal as the main seal of high-speed centrifugal compressor shaft seal in the petrochemical industry.

Applicable occasions:

centrifugal compressor and other high-speed high-speed fluid machinery, suitable for a small amount of process gas leakage into the atmosphere without harm working conditions, such as air compressor, nitrogen compressor, etc.

4.Labyrinth packing

Maze seal is arranged around the shaft multiple ring sealing teeth, between teeth and teeth form a series of intercepting gap and expansion cavity, sealing medium in throttle effect and achieve the purpose of leakage resistance, is the centrifugal compressor level and the most basic sealing form, according to the structural characteristics, can be divided into smooth, zigzag, step and honeycomb four types.

1.Smooth-type maze seal

The smooth maze seal has two structures: integral and insert. It is simple and easy to manufacture, but the sealing effect is poor.

2.A zigzag maze seal

Zigzag maze sealing also integral and set two structures, characterized by sealing tooth height, and high and low teeth, with the shaft surface, is a special concave and convex groove, the high and low teeth and concave and convex groove structure, make smooth sealing gap into a tortuous, therefore, increase the flow resistance, improve the sealing effect. The disadvantage is that it can only be used in the cylinder block or partition with horizontal section surface, and the sealing body should also be made into horizontal section type.

3.Step labyrinth

The stepped labyrinth seal is structurally similar to the smooth labyrinth seal, and the sealing effect is similar to the zigzag labyrinth seal, which is often used in the impeller cover plate and balance disc.

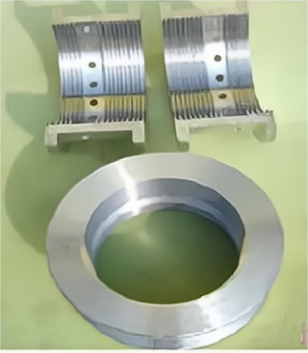

4.Honeycomb maze seal

The sealing tooth plate of the honeycomb maze is welded into a honeycomb to form a complex expansion chamber. Its sealing performance is better than the general sealing form, and it is suitable for occasions with large pressure difference, such as the balance disc sealing of the centrifugal compressor. The manufacturing process of honeycomb maze sealing is complex, the sealing piece strength is high, and the sealing effect is good.

5.Oil seal seal

Oil seal is a kind of self-compact lip seal, simple structure, small size, low cost, convenient maintenance, small resistance torque, can prevent medium leakage, also can prevent external dust and other harmful substances, and has a certain compensation ability to wear, but not resistant to high pressure, so generally used in low pressure of pump.

6.Dynamic seal

When the pump is running, the pressure head generated by the auxiliary impeller balances the high pressure liquid of the main impeller outlet to achieve the seal. When parking, the auxiliary impeller does not work, so a parking sealing device must be equipped to solve the possible pump leakage during stopping. The auxiliary impeller has simple sealing structure, reliable sealing and long service life. The pump can be dripping in operation, so it is often used in the pump containing impurities.

7.Helix seal

The helixseal is also a kind of dynamic seal, it is processed on the rotating shaft or on the inclusion sleeve of the shaft, the shaft and the sleeve is filled with sealing medium. The rotation of the axis causes the spiral groove to produce a transport effect similar to the pump, which preventing the leakage of the medium. The size of the sealing ability is related to the spiral angle, pitch, tooth width, tooth height, the length of tooth and the gap between shaft and sleeve. Because there is no friction between the seals, so the life is long, but due to the limitation of the structural space, its spiral length is generally short, so its sealing ability is also limited. When the pump is used at a speed down, its sealing effect will be greatly reduced.

Previous:Pump Basics

Next:Note for the disassembly and assembly of mechanical sealing

+86-0335-8085559

Junming (Hebei) Machinery and Equipment Manufacturing Co., Ltd.

Address:No.1 Huaihe Road, Qinhuangdao Economic and Technological Development Zone

Domestic:+86-0335-3066990

Overseas:+86-0335-8085559

Domestic:info@junmingmeco.com

Overseas:sales@junmingmeco.com

Website:www.junmingmeco.com

-

官方微信

Recommendation

Recommendation